HARDWARE HACKING (click on the photos for a larger image, and yes, I do take rubbish photos.)

I stumbled across a few sites that talked about Hardware Hacking whilst doing some

research at work (no really, I was). They set me off on a project I have been meaning

to do for some years now. Hardware Hacking is the idea of either making some shop bought

device do something better, different or else in addition to its purpose. I wanted my

Radar Detector to be hidden, both from the low-lifes that might want to steal it, and from

the tax collectors that masquerade as Policemen (no, they are not illegal now, but soon...)

I stumbled across a few sites that talked about Hardware Hacking whilst doing some

research at work (no really, I was). They set me off on a project I have been meaning

to do for some years now. Hardware Hacking is the idea of either making some shop bought

device do something better, different or else in addition to its purpose. I wanted my

Radar Detector to be hidden, both from the low-lifes that might want to steal it, and from

the tax collectors that masquerade as Policemen (no, they are not illegal now, but soon...)

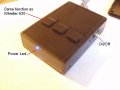

Remote control detectors are available but very expensive. This is how the conversion was done - and it works great! I bought my Whistler 930 in Arizona eight years ago for £35, and it has never let me down. About three years ago I bought an updated European version which is fantastic. More about this later, how it performs and how you can get one for a sensible price. This is the Whistler 930. It has three buttons at the back and a row of nine leds that indicate different types of radar or Laser speed gun. On the top there is a small bulge that houses a lightguide to that if a Laser is pointed at the back, it can be detected.

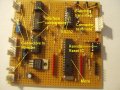

Four self tapping screws need to be removed and then the top and bottom of the case can be

taken off - easy. Like most electronic equipment, the 930 is constructed from tiny components

called 'surface mount devices or 'SMD'. It is fairly easy to solder to these but because they

are so tiny, the wire has to be thin. I wanted easy connections with a wire that I could bend

how I liked. The LEDs on the 930 are not SMD and are easy to get at, however when I measured

the voltage on them I found that with the LED off it was 5v and with the LED on it was 3v.

The reason for this is that there is (must be) a resistor from one side of the LED to the

micro-controller - but this is SMD and I do not want to solder to it! To get around the problem

I wired each LED to a comparator which translates the 3v and 5v levels into 0v and 5v. The wires

are connected as you can see in another lousy photo here.

Four self tapping screws need to be removed and then the top and bottom of the case can be

taken off - easy. Like most electronic equipment, the 930 is constructed from tiny components

called 'surface mount devices or 'SMD'. It is fairly easy to solder to these but because they

are so tiny, the wire has to be thin. I wanted easy connections with a wire that I could bend

how I liked. The LEDs on the 930 are not SMD and are easy to get at, however when I measured

the voltage on them I found that with the LED off it was 5v and with the LED on it was 3v.

The reason for this is that there is (must be) a resistor from one side of the LED to the

micro-controller - but this is SMD and I do not want to solder to it! To get around the problem

I wired each LED to a comparator which translates the 3v and 5v levels into 0v and 5v. The wires

are connected as you can see in another lousy photo here.

The audio alerts pose a whole new problem. I easily found a signal on the volume control that was easy to wire too again, but how do I get it back to the remote ? A few calculations showed that to send it as a 'message' needed a very fast connection. A could sample it and then generate the sounds in softare at the remote, but a better and very simple solution was to hand. More about that later, and by the way, code, schematics etc is available at no charge.